Tesla safety cell restoration is a specialized field requiring expert knowledge and advanced techniques. These cells, primarily made from high-strength steel, act as the vehicle's structural backbone, absorbing impact energy during collisions to protect occupants. Skilled technicians use robotic welding and computer-aided design software to meticulously repair these components while maintaining their integrity and strength. By leveraging cutting-edge technology, professionals restore damaged safety cells to original specifications, ensuring optimal performance, durability, and peace of mind for Tesla vehicle owners.

Tesla vehicles are renowned for their innovative safety features, with the safety cell playing a pivotal role in protecting occupants. This article delves into the intricacies of Tesla safety cell restoration and high-strength steel repair, essential aspects of maintaining optimal vehicle safety. We’ll explore the unique structure of these cells, advanced repair techniques, and how they contribute to enhancing crash performance and durability. By understanding these processes, enthusiasts can appreciate the craftsmanship behind Tesla’s safety technology.

- Understanding Tesla Safety Cell Structure and Its Role

- Restoring and Repairing High-Strength Steel in Safety Cells

- Advanced Techniques for Ensuring Optimal Performance and Durability

Understanding Tesla Safety Cell Structure and Its Role

The Tesla Safety Cell is a revolutionary design feature that sets electric vehicles (EVs) apart from their internal combustion engine counterparts. It serves as the car’s structural backbone and critical safety component, incorporating high-strength steel to protect occupants in the event of a collision. This intricate cell structure is designed to deform and absorb impact energy, distributing it evenly across the vehicle, thereby reducing the risk of severe injury. Understanding this system is paramount when considering Tesla safety cell restoration or auto frame repair, as any alterations must maintain or enhance its integrity.

The careful balance between structural rigidity and controlled deformation is a cornerstone of modern vehicle safety. Repairs that involve the safety cell, whether minor or extensive, require expert knowledge and specialized tools to ensure the car’s safety systems remain functional and effective. When damaged, these cells can be expertly restored, utilizing advanced techniques and high-quality materials, such as high-strength steel sheets, to precisely match the original factory specifications. This meticulous process is crucial for maintaining the vehicle’s overall structural integrity and performance, alongside its renowned Tesla safety standards, even after an incident or required car paint services.

Restoring and Repairing High-Strength Steel in Safety Cells

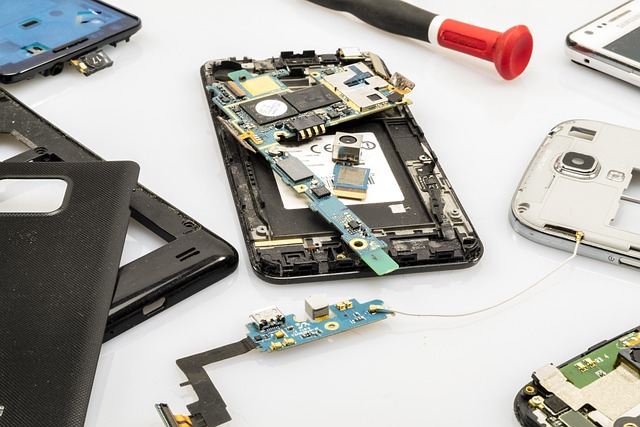

Restoring and repairing high-strength steel in Tesla safety cells is a specialized task that demands precision and expertise. The safety cell, often referred to as the chassis or frame, is the backbone of any vehicle, including Teslas, responsible for protecting occupants during accidents. Given the advanced materials and engineering involved, auto body work on these components requires a deep understanding of both traditional and modern repair techniques.

In the case of Tesla safety cells, high-strength steel, such as advanced high-strength steels (AHSS), is used extensively to enhance crashworthiness. When repairing or restoring these areas, it’s crucial to maintain the structural integrity and strength that AHSS provides. Skilled technicians employ specialized tools and methods, including robotic welding and computer-aided design (CAD) software, to ensure precise and accurate repairs, preserving both the performance and safety of the vehicle. This meticulous approach to automotive repair is essential for maintaining the overall quality and reliability of Tesla vehicles.

Advanced Techniques for Ensuring Optimal Performance and Durability

In the realm of Tesla safety cell restoration, advanced techniques play a pivotal role in ensuring optimal performance and durability. This intricate process involves specialized methods to meticulously repair high-strength steel, a key component in the car’s structural integrity. By employing cutting-edge technology and precision engineering, professionals can revive damaged safety cells, restoring them to their original strength and stability.

The use of advanced techniques extends beyond simple fender repair or car scratch repair; it encompasses a comprehensive understanding of material science and structural integrity. For instance, specialized welding methods and robotic precision enable precise repairs without compromising the overall structure. This ensures that every Tesla vehicle retains its safety standards, providing peace of mind for owners. Moreover, these advanced practices contribute to the longevity of the vehicle, making it a reliable companion on the road.

Tesla safety cell restoration is a specialized process that ensures the structural integrity and longevity of electric vehicles. By understanding the unique design and implementing advanced repair techniques for high-strength steel, professionals can effectively restore and strengthen these critical components. This not only enhances vehicle safety but also contributes to the overall sustainability of the automotive industry by promoting the reuse and durability of materials. With ongoing technological advancements, Tesla safety cell restoration methods continue to evolve, promising even better performance and peace of mind for drivers.